Jigging machine

Jigging machine is a new type of energy saving and high efficient gravity separation equipment which is developed according to the law of layer theory of jigger bed stratification. Due to its big capacity, wide size range, high recovery, simple operation and maintenance, it’s widely taken for sand gold, tungsten, tin, iron, manganese, titanium, chrome, sulfur, coal, diamond and for manganese slag, chrome slag, stainless steel slag, smelting slag recycling, tailings recycling and processing.

Our Jigging machine is saw-tooh wave jigger.The maximum feeding particle size is 6-25mm and can be reach 30mm in producing sand ore process. When processing the open-pit mines, the saw-tooth wave jigger is a key machine with the principle of gravity separation. Its pulse curve is like saw-tooth waveform to make rising water faster than the dropping water; enhanced the loose of bed, eased the inhaled role, so that heavy particles in the mineral can fully settlement, greatly improving the sorting capacity and recovery rate of equipment.

Features

【Capacity】:1-30t/h

【Feed Size】:0-6mm, 6-30mm

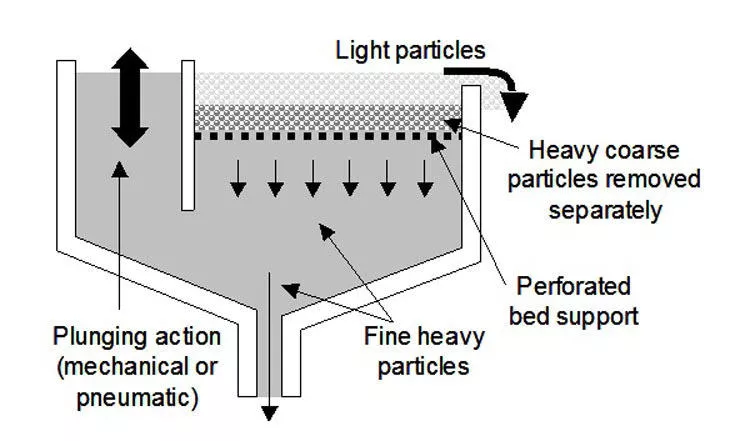

【Structure】:The jig machine mainly consists of feeding chute, jigging chamber, presser, screen, holder, cone bucket, rubber diaphragm, spring, cam case, electromagnetic speed motor, fluidization water port, concentrates port, tailings port and so on.

【Application】:Diaphragm gold jig concentrator is widely used in ore beneficiation plant, also suitable to process material like tungsten, tin, placer gold, hematite, limonite, manganese ore, titanium, antimony, lead, tantalum, niobium and etc.

| Applicable Industries | Energy & Mining |

| Showroom Location | - |

| Place of Origin | Shandong, China |

| Weight | 3000 KG |

| Warranty | 1 Year |

| Marketing Type | Ordinary Product |

| Machinery Test Report | Not Available |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | Engine |

| Key Selling Points | High Rigidity |

| Condition | New |

| Type | Gravity Separator |

| Production Capacity | 99% |

| Brand Name | KD |

| Voltage | 220V/380V |

| Dimension(L*W*H) | 5600*1850*860mm |

The water is pulsated up and down (i.e. the jigging action) pneumatically or with the use of a mechanical plunger .

The jigging action causes denser particles to preferentially trickle down faster and are removed from the bottom of units

Details Images